FIX•N outside linear

FIX•N outside linear – ALUMINIUM MOUNTING RAIL FOR LINEAR ATTACHMENT

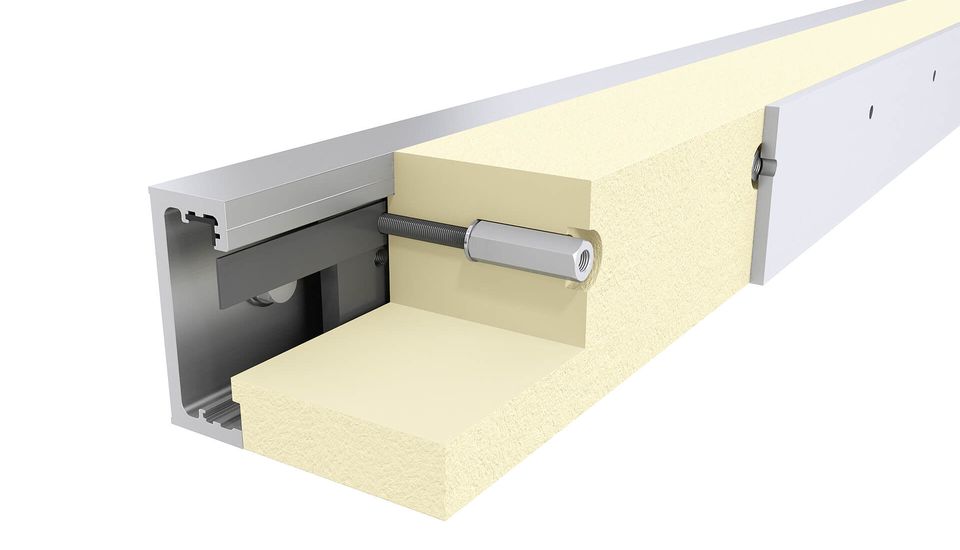

The system has a modular design, which means it can be flexibly adapted to the application in question. The main components are the aluminium mounting rail which is independent of the application and intended for pre-assembly and connection to the substructure, insertion plates made from stainless steel with high-strength threaded rods, and pressure-resistant insulating elements.

Details

- Rail lengths of up to 3000 mm

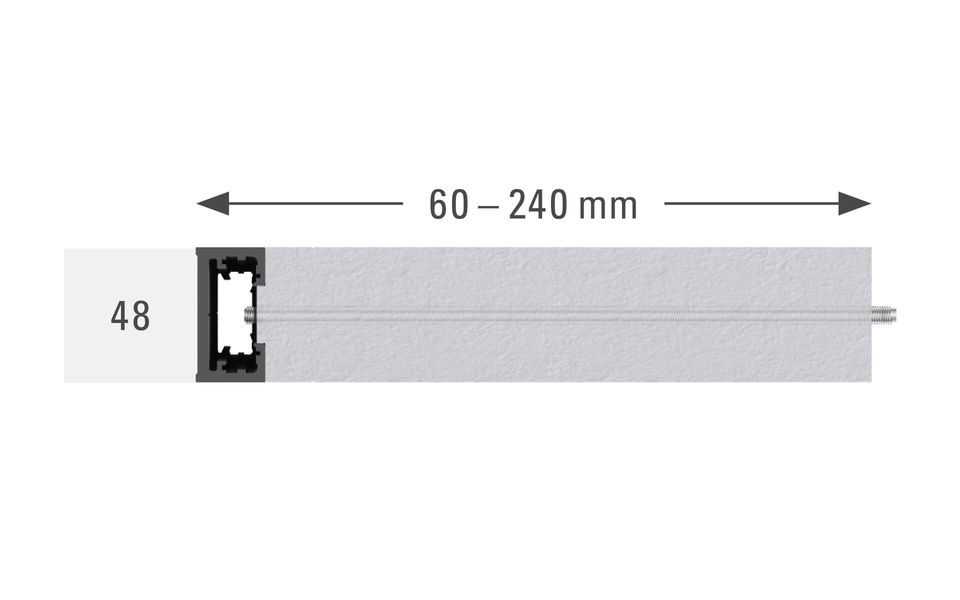

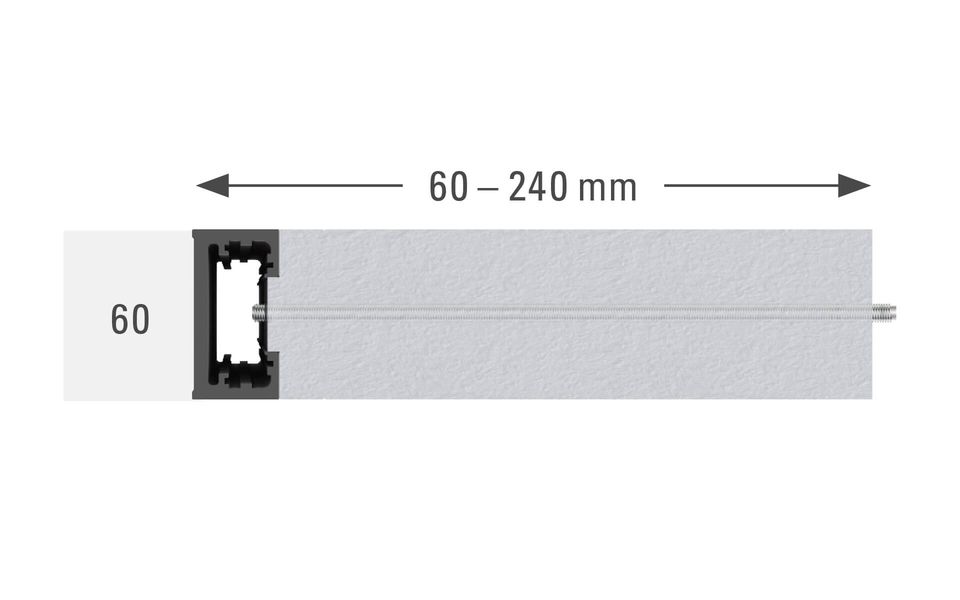

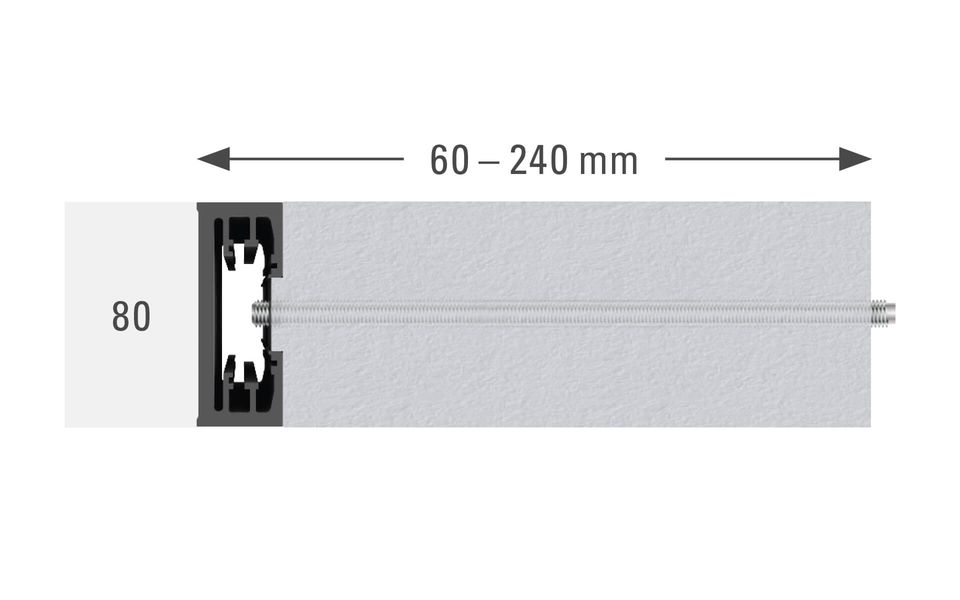

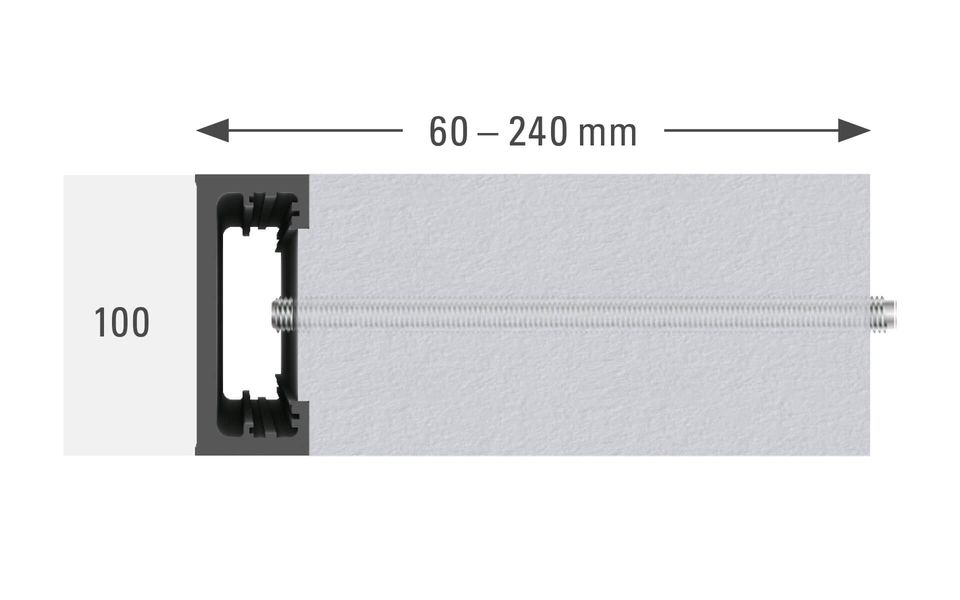

- Five system widths from 48 to 120 mm

- The holes can also be drilled differently for mounting the rail

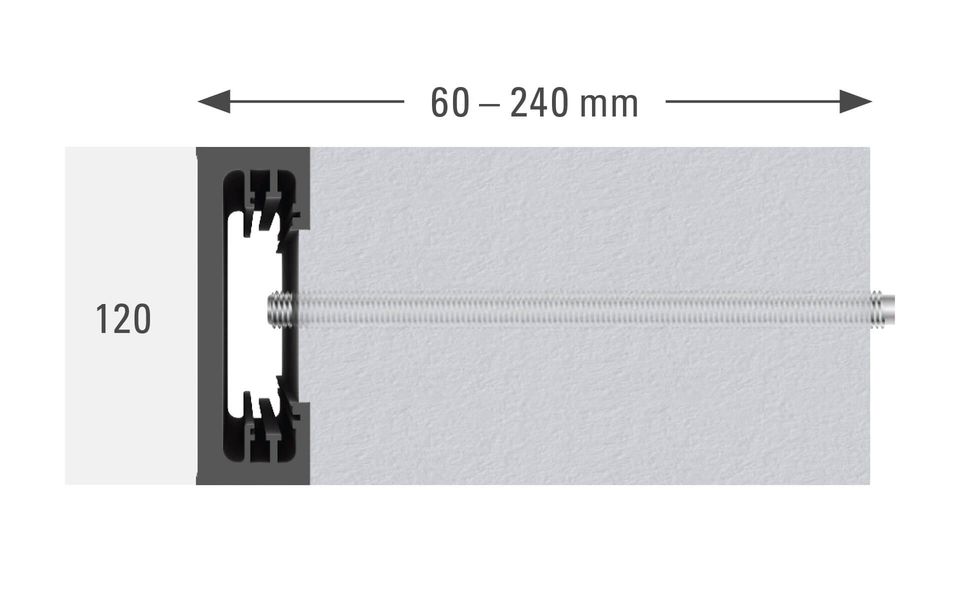

- Insulation thicknesses from 60 to 240 mm

- Insertion plates with high-strength threaded rods can be moved so as to adapt them to the fastening points for the mounting elements

- Drilling the insulating elements for feeding through the threaded rods can be done in a variety of ways

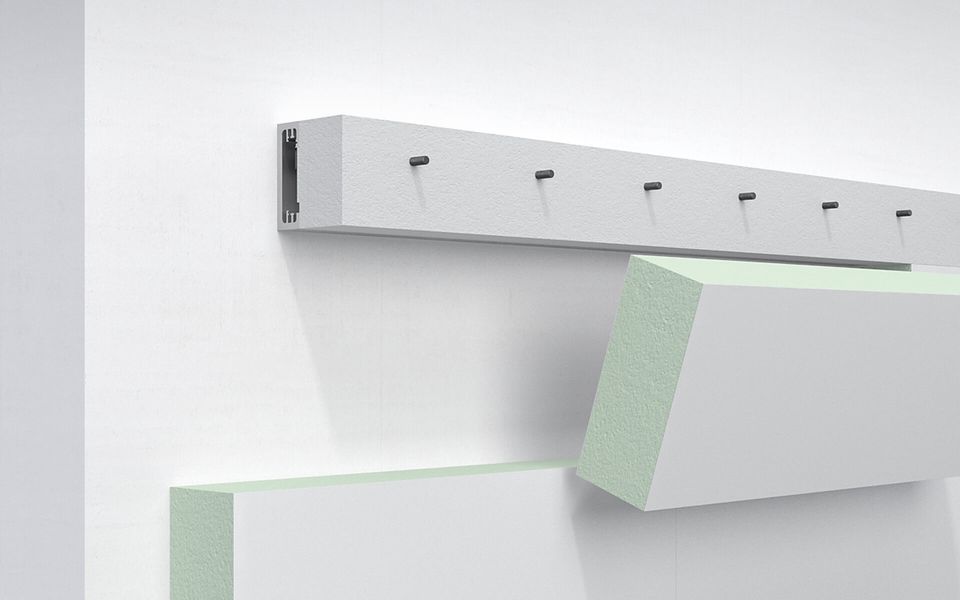

Flexible, easy to assemble and completely safe – the new FIX•N outside from GLASSLINE guarantees that the mounting elements are securely mounted for heat-insulated walls and façades. Thermal bridges are prevented. The system has a modular design which makes it as simple as possible and extremely effective for planning and installation. With few components and different insulating element sizes, you can effortlessly bridge any insulation thickness both thermally and statically. In this way, users benefit from flexible application options without compromising on results. Whether working vertically, horizontally or overhead, on a new construction or subsequent installation, FIX•N outside is suitable in any on-site situation – as a rail for linear installation and as a system component with adapter plates for connection at specific points.

Installing the aluminium mounting rail for linear attachment

The main components of the system are the aluminium mounting rail which is independent of the application and intended for pre-assembly and connection to the substructure, insertion plates made from stainless steel with high-strength threaded rods, and pressure-resistant insulating elements. This makes installation remarkably easy, flexible and fast.

Slide the thermal separating brackets into the aluminium mounting rail then attach the mounting rail to the substructure by means of variable screw attachments. Attach the threaded rods to the insertion plates and fit them to the aluminium mounting rail. The number required depends on the number of fastening points for the mounting element. These insertion supporting elements can be simply moved for precise positioning. The elements are secured in place with an individually drilled assembly gauge. They are then assembled with the insulating elements, which are pre-drilled accordingly for feeding through the threaded rods. The system is now ready for attaching the mounting element.